Sheet Metal Engineering

- Home

- Services

- Engineering Services

- Sheet Metal Engineering

Sheet Metal Engineering

Product & Simultaneous Engineering

During the product development phase, the concept of simultaneous engineering supports engineers in selecting the best product and process design. This approach helps prevent errors by applying well-thought-out designs later in the development process.

R and W Industries excels in developing tooling and process concepts early in the product development phase. By doing so, the company effectively supports the simultaneous engineering concept, offering benefits such as robust part manufacturability, enhanced performance and reduced manufacturing costs.

R and W Industries excels in developing tooling and process concepts early in the product development phase. By doing so, the company effectively supports the simultaneous engineering concept, offering benefits such as robust part manufacturability, enhanced performance and reduced manufacturing costs.

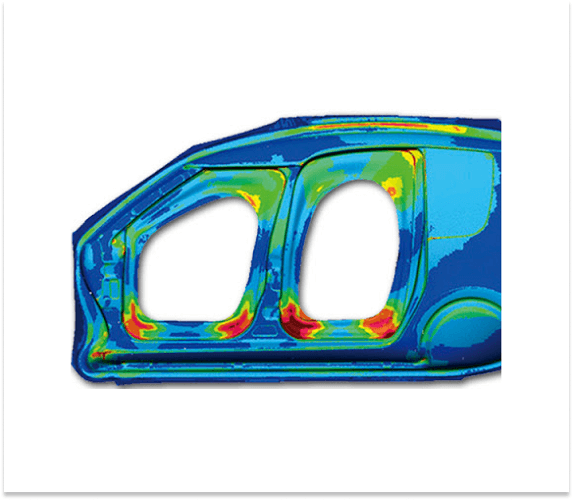

CAE Analysis

We transform the process of product development by utilizing the capabilities of Computer-Aided Engineering (CAE) simulations right from the beginning of the design phase. Our advanced methodology enables clients to digitally verify their products, resulting in significant savings in both time and costs throughout the entire product development journey.

Expertise Across Diverse Engineering Domains:

We possess extensive experience across a range of engineering programs and domains, allowing us to offer unmatched expertise.

Seamless Integration of Simulation & CAD:

Our extensive experience in various engineering programs and domains equips us with unparalleled expertise.

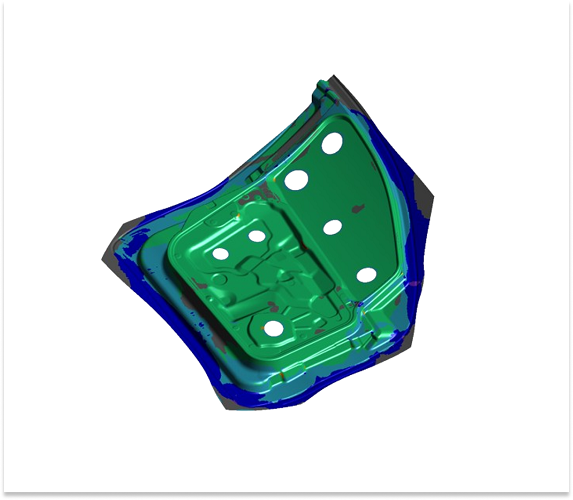

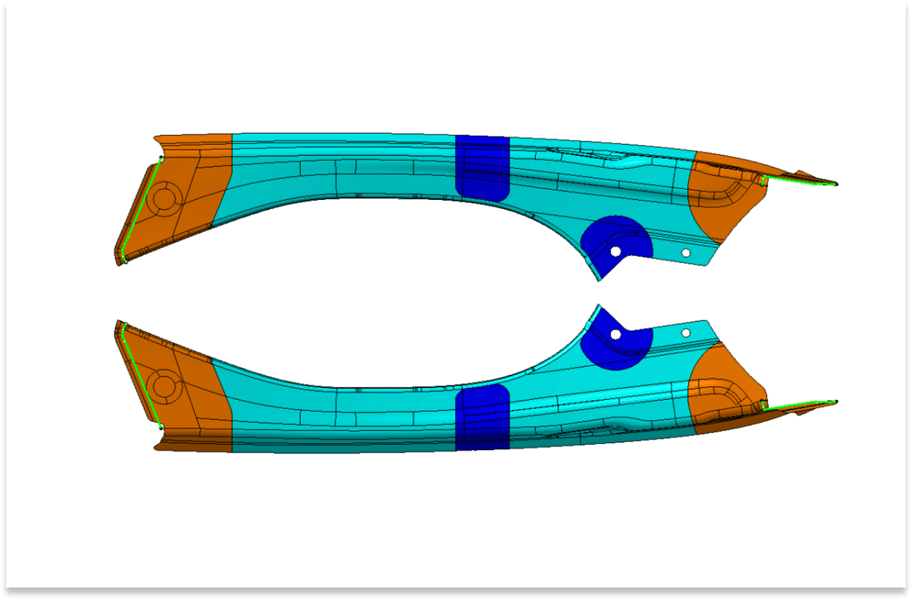

Tool Design

We provide a comprehensive range of services for Tool design Cycle, starting from Concept Creation to Tool design completion. Since 2019, we have been offering Engineering Services to clients worldwide across different industries. Our expertise lies in Automotive, particularly in Overhead systems, Interior/Exterior Trims, Seating system, BIW design, Tool & Fixture design and FE analysis. Collaborating with numerous OEM & Tier 1 companies, we deliver Offshore and Onsite services in Tool design, CAM Programming and Value engineering.

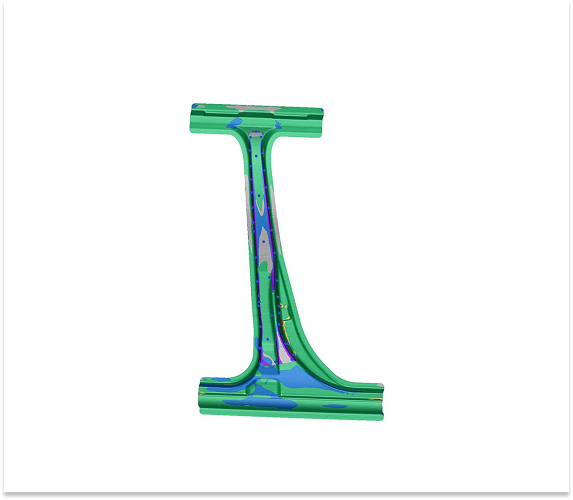

NC Data Preparation

We specialize in providing comprehensive NC (Numerical Control) data which is being used to prepare the NC programs that streamline your manufacturing process and enhance precision. Our team of experts ensures that your designs are flawlessly converted into machine-ready instructions, optimizing efficiency and reducing production times.

Our Services

1. 3D machining model preparations according to customer standards .

2. Trim line preparations as per the die functionality including bypass and overlap.

3. 3D machining model preparation for trim dies as well as for scrap cutters.

4. Female radius reduction

5. Machining models includes desired clearances according to die functionality.

6. Flange die model preparation for machining including hard hitting patches preparations.

7. Open flange data preparation for hemming parts according to customer standards.

8. Flange line development for machining.

9. Setup wise machining axis/ direction preparation.

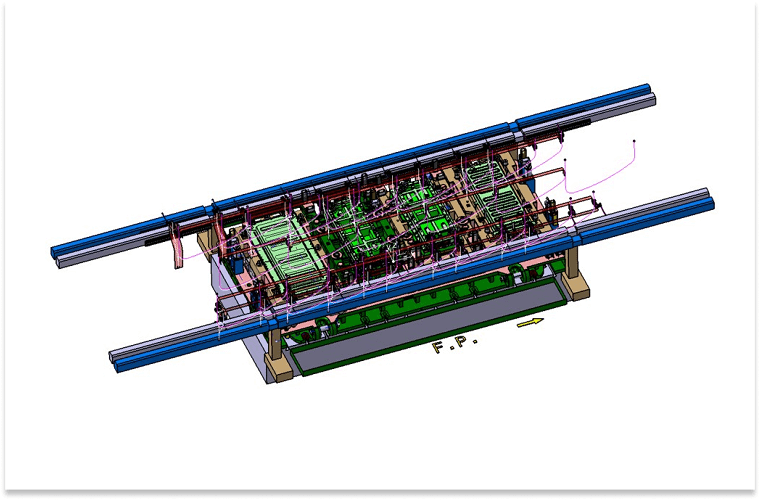

BIW Fixture Design

We are a specialized company that focuses on the design of Body-In-White (BIW) fixtures for Automotive OEMs, Tier-1 and Tier-2 industries. Our team of highly experienced technical experts, each with more than 12 years of experience in BIW fixture design, is committed to providing cost-effective and high-quality solutions.

Our Proficiency in BIW Fixture Design:

With a strong track record of successfully implementing numerous projects for clients around the world, we excel in designing welding lines and fixtures for various car part assemblies, including –

-

Underbody Structure

-

Body Side Structure

-

Framing

-

Closures & Others

-

Roof Structure

Capabilities & Capacity:

Our Body-In-White Division has the capability to handle multiple medium-sized projects simultaneously, ensuring prompt and efficient delivery. Our design team working diligently and professionally to meet and surpass client expectations.

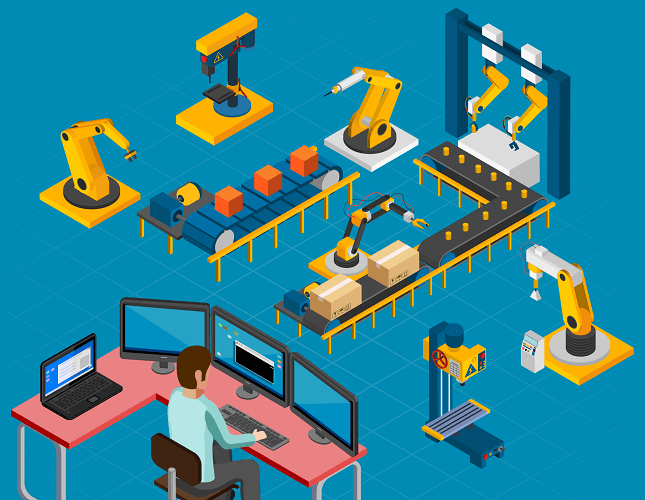

Robotic Simulation

Our team, with over ten years of experience, provides top-tier simulation services. We are committed to delivering exceptional results and ensuring 100% customer satisfaction. Our guarantee includes on-time execution and strict adherence to client requirements.

Our team possesses expertise in various areas, including:

-

Process and Layout Study

-

Work Cell Building as per Layout

-

Robot Reachability and Feasibility Analysis

-

Product and Tool Validation

-

Spot Distribution

-

Path Planning

-

Kinematics

-

Welding & Handling/Sealing Path Creation

-

Safety Study in line with Customer Standards

-

Layout Validation

-

OLP Attributes

-

RCS Cycle Time Validation (ABB, KUKA, FANUC)