Plastic Engineering

- Home

- Services

- Engineering Services

- Plastic Engineering

Plastic Engineering

Product & Simultaneous Engineering

The design of plastic materials is subject to specific rules that arise from their inherent behavior and the processing techniques utilized. A critical factor for successful application is a solid technical grasp of the relevant plastic, which facilitates the evaluation of engineering designs and the identification of potential enhancements. This process involves an examination of both the processing methods and the characteristics of the final product.

- Optimization of components to minimize cycle durations

- Design considerations related to load and stress

- Specifications for wall thickness and rib configuration to mitigate shrinkage and warping

- Assessing manufacturability and the behavior during demoulding

- Analysis of orientations and internal stress factors

- Identification of faults and defects, including the placement of welds, joints, or air entrapments

The use of plastic components provides significant design flexibility and opportunities for functional integration, particularly when employing specialized processes and material combinations. By considering these options from the outset, one can fully leverage the technological advantages that plastics offer.

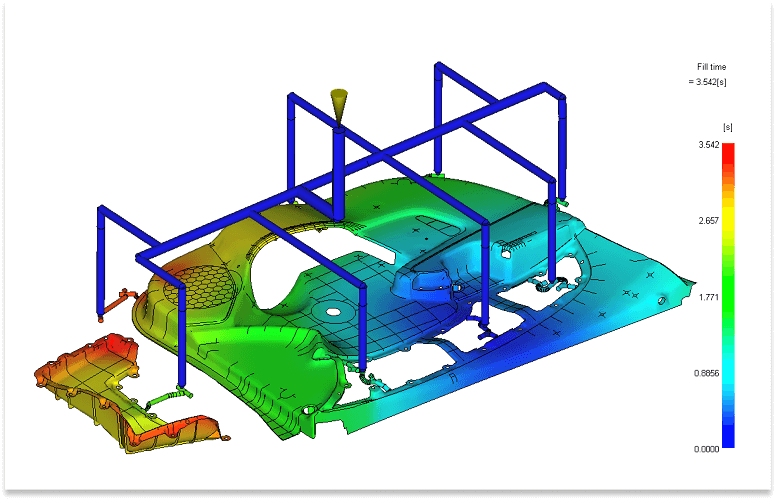

Mold flow analysis

We model the flow of molten plastic inside a mould using cutting-edge computer-aided engineering (CAE) techniques as part of our Mould Flow Analysis Design service. We can forecast the flow behaviour of molten plastic by using sophisticated mathematical models that take into account important variables including the part’s design, the kind of plastic, and the injection moulding procedure’s parameters.

Our experts use in-depth analysis to find potential mould design problems, such as cooling imbalances and the potential for air pockets to emerge. We optimise the mould design to enhance molten plastic flow and lower failure rates by projecting the injection moulding process’ cycle time.

Our experts use in-depth analysis to find potential mould design problems, such as cooling imbalances and the potential for air pockets to emerge. We optimise the mould design to enhance molten plastic flow and lower failure rates by projecting the injection moulding process’ cycle time.

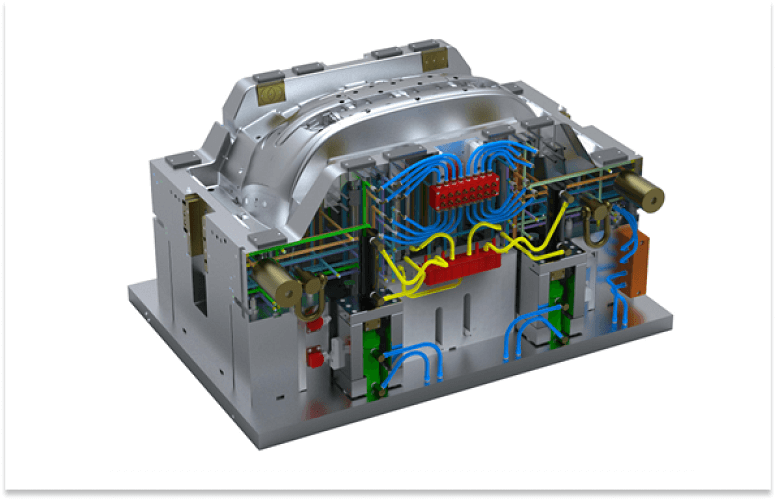

Injection Mold Design

The design of moulds plays a crucial role in the injection moulding process, and our skilled personnel ensure precision at every step. We conduct comprehensive quality assurance evaluations to confirm that the mould design is structurally sound and proficient in consistently producing high-quality components.

Our skilled team does not cut any corners when it comes to mould design, which is an essential part of the injection moulding process. To guarantee that the mould design is both structurally solid and able to continuously produce high-quality parts, we carry out thorough quality assurance procedures.

Our skilled team does not cut any corners when it comes to mould design, which is an essential part of the injection moulding process. To guarantee that the mould design is both structurally solid and able to continuously produce high-quality parts, we carry out thorough quality assurance procedures.