Industrial Computed Tomography

- Home

- Services

- Engineering Services

- Industrial Computed Tomography

Industrial Computed Tomography

Industrial Computed Tomography

Advanced industrial CT combined with volume graphics software provides precise Nondestructive testing (NDT), offering detailed 2D and 3D imaging and Analysis to detect internal and external defects, ensuring thorough quality control and flawless inspection without damaging the component.

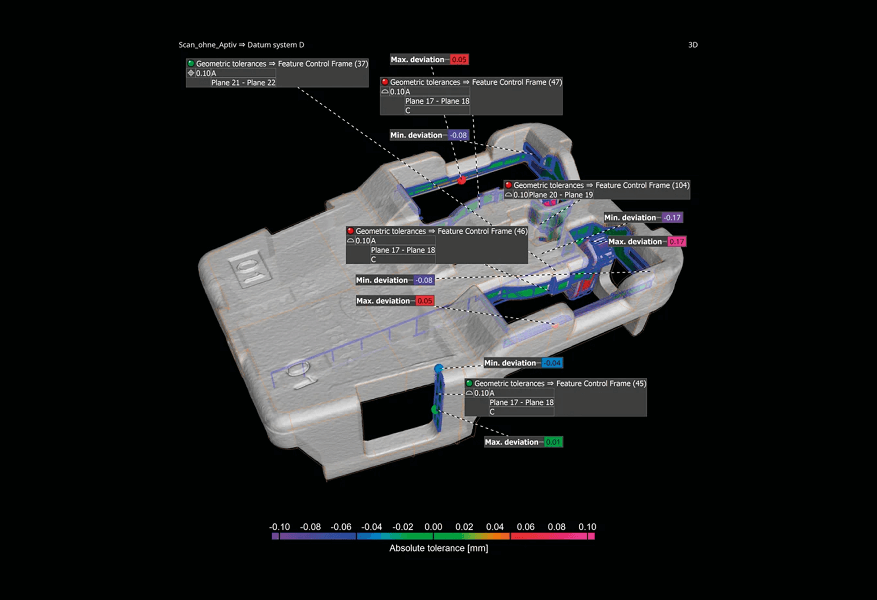

Dimensional Metrology

Utilizing industrial CT scanning, volume graphics leverages advanced dimensional metrology techniques combined with GD&T to provide precise and accurate measurements of internal and external features.

Defect Identification

Easily find quality defects by visualizing and analyzing the internal and external structure of complex parts without cutting, detecting even the small cracks, voids or material inconsistencies

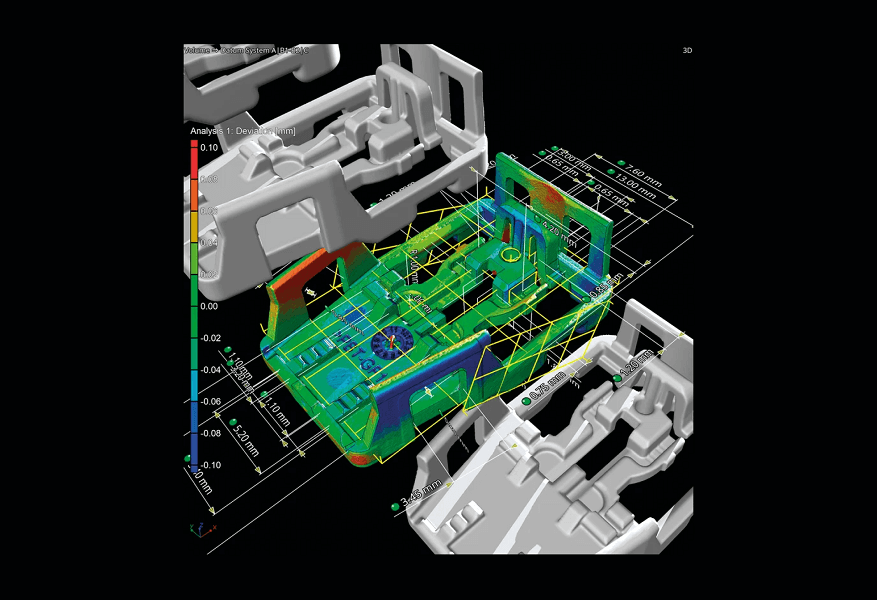

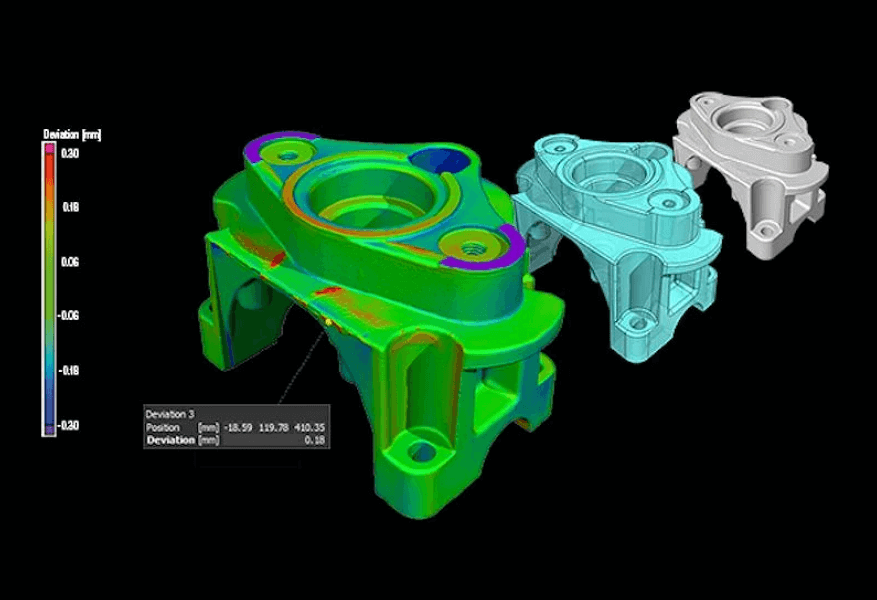

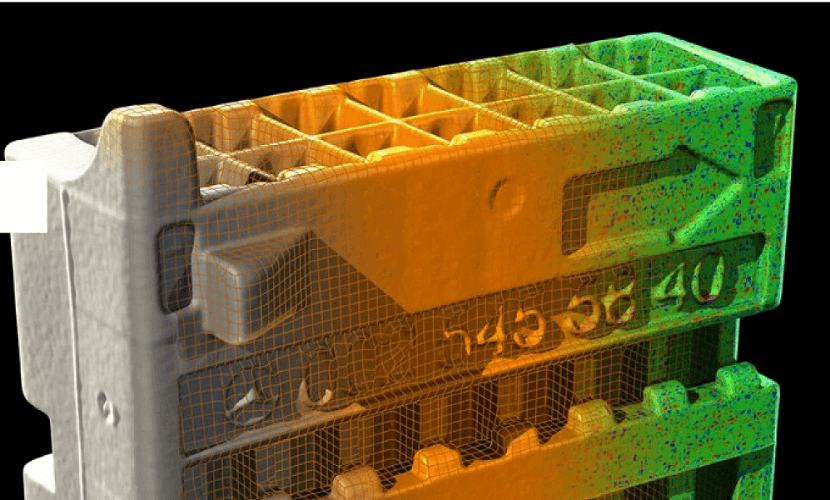

Actual /Nominal Comparison (Part to Part/Cad to Part)

Volume graphics software enables precise CAD to Actual part comparison by Aligning 3D scans with original design model to determine how precisely your component was manufactured. The software also facilitates part to Part analysis, comparing actual measured data between 2 different components or production batches to detect deviations. Color coded visualization making it easy to identify areas that fail to meet design requirements.

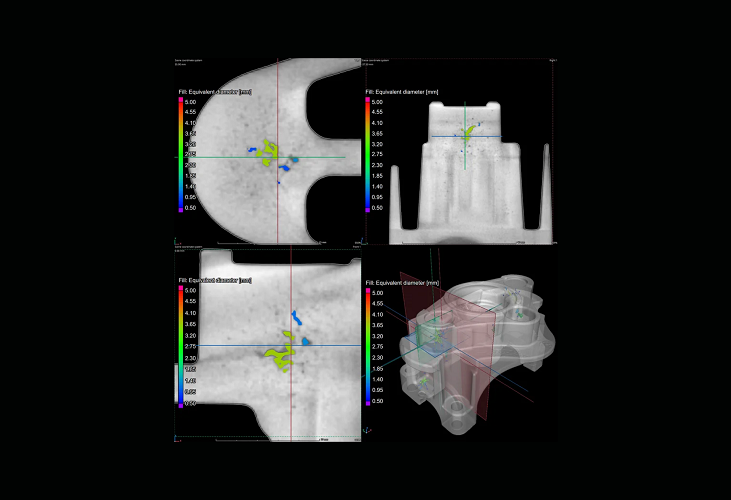

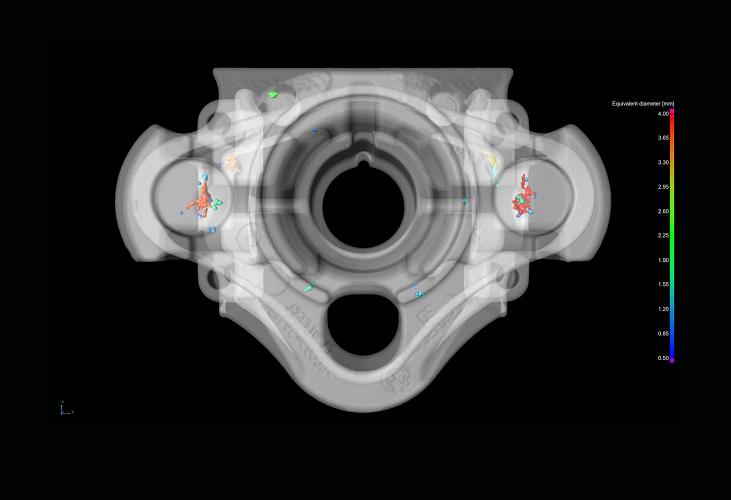

Porosity/Void Analysis

Internal defects such as voids and porosity are an inherent part of many manufacturing processes such as casting and injection molding fabrication, We Can detect and measure the voids, porosity and defects within the objects providing clear insights of material Quality

Reverse Engineering

CT data can be converted into .STL file (CAD file), capturing both external shapes and internal structures. This helps in analyzing and replication of complex components, making it easier to improve design and innovation.