Product Lines

- Home

- Services

- Our Products

- Product Lines

Product Lines

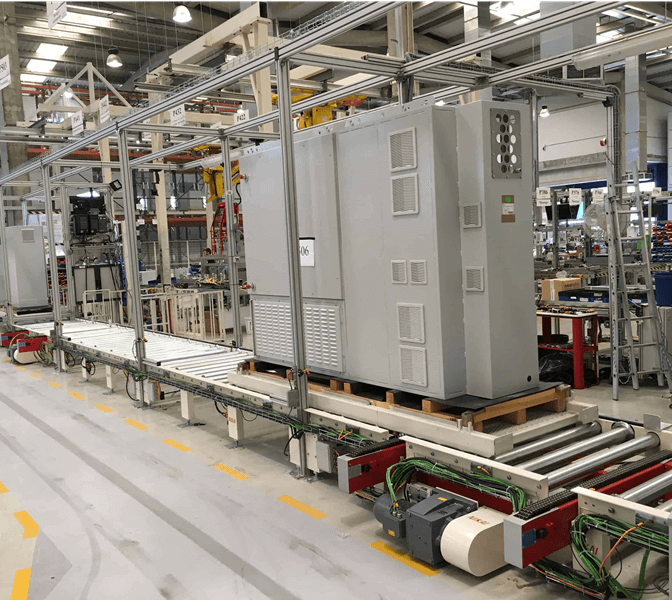

Production Line Enclosures

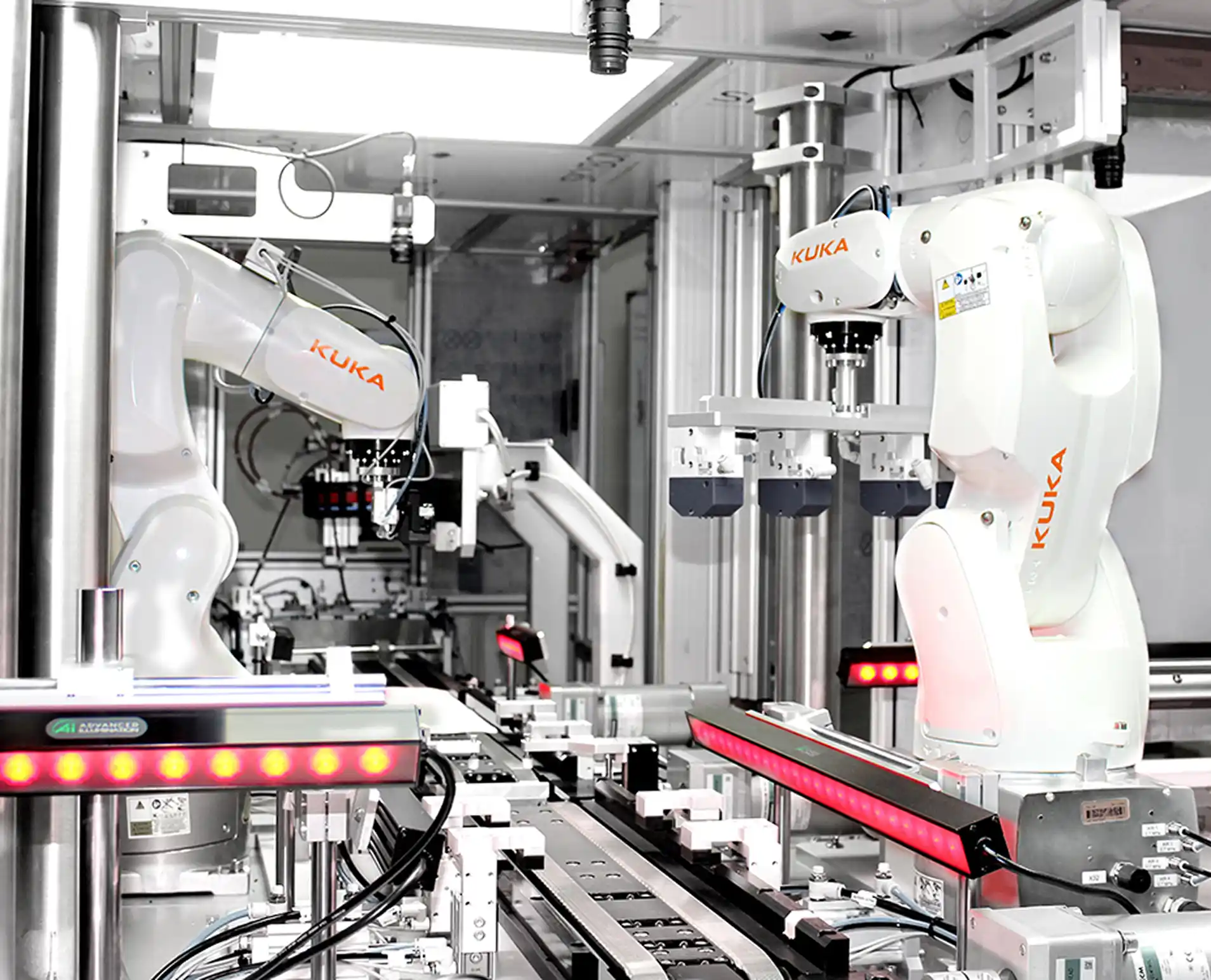

Machine Enclosures

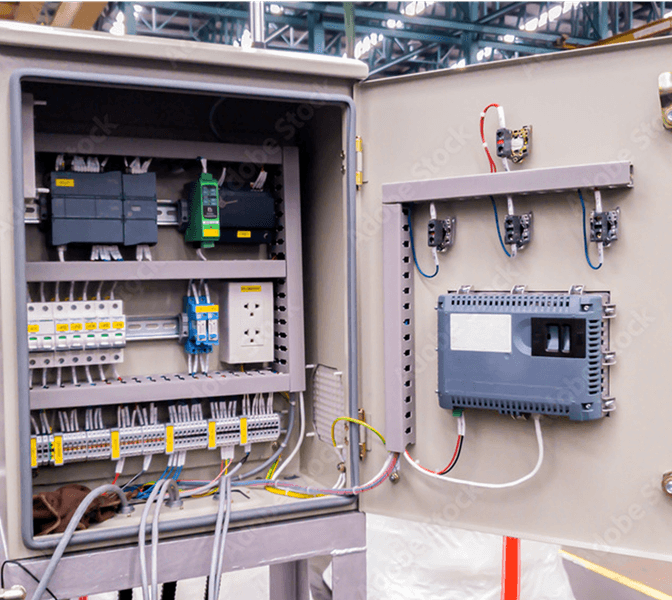

Electrical Control Panel & Automation Enclosure

Customized Structure And Fabrication

Various Types of Enclosures

Safety Enclosures

– Purpose: Protect operators from radiation, moving parts, sparks, or hazardous materials.

– Features: Interlocks, emergency stops, shatterproof panels, radiation proof panels.

– Examples: X-Ray machines, Robotic cell barriers, CNC machine guards.

Acoustic Enclosures

– Purpose: Reduce noise generated by machinery

– Features: Sound-absorbing walls, sealed joints, vibration isolation

– Examples: Compressor housings, packaging stations in high-decibel zones.

Cleanroom Enclosures

– Purpose: Maintain sterile or particle-controlled conditions.

– Features: HEPA filters, smooth surfaces, controlled airflow.

– Examples: Pharmaceutical packaging, microelectronics assembly

Environmental Enclosures

– Purpose: Shield equipment from dust, humidity, or temperature extremes.

– Features: Sealed panels, climate control units, corrosion-resistant materials.

– Examples: Electronics production near coastal zones, food processing lines

Containment Enclosures

– Purpose: Capture fumes, dust, or byproducts from processes

– Features: Integrated extraction systems, chemical-resistant walls.

– Examples: Paint booths, welding enclosures.

Security Enclosures

– Purpose: Restrict unauthorized access to sensitive areas.

– Features: Lockable doors, surveillance support, badge-controlled entry.

– Examples: Prototype testing zones, asset storage enclosures.

Custom Multi-Function Enclosures

– Purpose: Tailored combinations to meet overlapping functional demands.

– Features: Hybrid panels, modular segmentation, flexible cabling and automation interfaces.

– Examples: Assembly lines with integrated automation, acoustics and filtration in one unit

Key Design Considerations

Material Selection

Accessibility

Ventilation & Filtration

Lighting & Visibility

Safety & Compliance

Automation Integration

- Production Line Enclosures

- Machine Enclosures

- Electrical Control Panel & Automation Enclosures

Types of Production Line Enclosures

Full Enclosures

Partial Enclosures

Modular Enclosures

Assembly Machines

– Robotic arms (pick-and-place, welding, screwing)

– Press-fitting and riveting machines

– Screwdrivers with torque control

– Adhesive dispensers

Processing Machines

– CNC machines (milling, turning, drilling)

– Injection molding machines

– Extrusion machines

– Grinding and polishing systems

Utility Systems

– Air compressors

– Chillers and cooling systems

– Power distribution panels

– Dust and fume extractors

Packaging Machines

– Wrappers and sealers (heat-seal, shrink-wrap)

– Box forming and filling machines

– Labeling and barcoding systems

– Palletizers and strapping machines

Inspection & Testing Machines

– X-Ray / CT Inspection systems

– Vision inspection systems

– Weight checkers

– Leak testers

– Electrical function testers

Finishing Machines

– Painting booths and spray robots

– Laser marking and engraving units

– Deburring and surface treatment equipment

Material Handling Machines

– Conveyors (belt, roller, screw)

– Elevators and hoists

– Automated Guided Vehicles (AGVs)

Extensible – Floor Standing

Junction Box Or Wall Mounting Enclosure

Operator Station

PC Enclosure – Shop Floor